Allied World: The forgotten threat of sawdust fires and explosion

November 9 2020By Hiresh Das, assistant vice president, Allied World

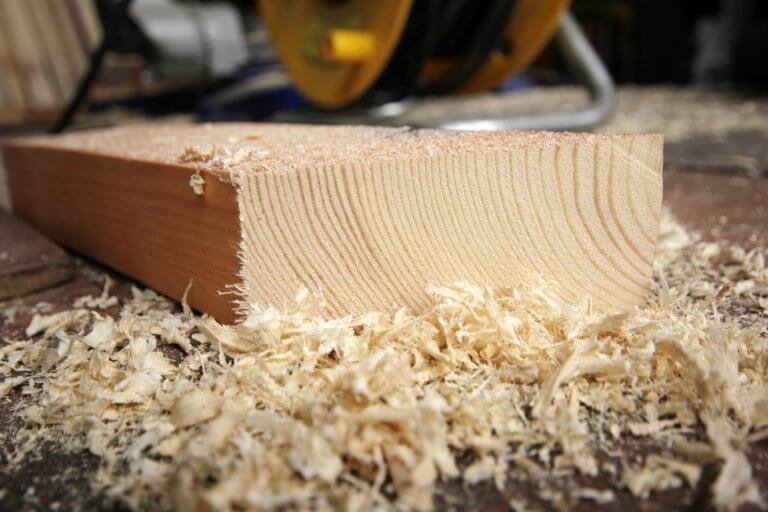

Understandably, wood and timber materials are usually seen as the primary source of fires in woodworking and relatedndustries. Risk managers need to carefully look at how sawdust fires can occur, and take sensible steps to manage the hazard.

A widespread risk in the woodworking and wood-related industries

Sawdust fires and explosions have always been a serious problem in wood-related industries but always seems to take a back seat to the obvious fire exposure in the wood and timber industry.

The fact is sawdust is as common in wood shops as wood itself. As a by-product of the manufacturing process, the excess dust is just as much a fire risk as the threat posed by large stocks of wood. Clouds of sawdust are combustible and therefore susceptible to fire, and if the dust is contained within full or partial enclosures in significant volume, a single spark or ignition source can trigger an explosion.

As a general observation, larger volumes of dust clouds will result in more widespread fires and/or explosions than smaller ones. Therefore, it’s essential that sawdust doesn’t escape from collection areas or build up in workrooms.

An initial explosion within a collection area can stir up deposits through the workplace, and burning particles can ignite these dust clouds, causing a second explosion that is more damaging than the first.

While dust is commonly viewed as a by-product of wood-related industries, the risk of a sawdust fire is more common than you would think – it’s often recycled as a raw material, meaning that it is in even wider circulation. For example, in the paper industry, factories use sawdust as biofuel for boilers and/or generators for power supply.

A risk that requires serious attention

It’s vital to mitigate and manage the very real and dangerous hazard of sawdust fires and explosions – particularly when dealing with industries where it is not so obvious. The danger is that when dealing with non-wood and timber industries – that use and have sawdust exposure – this risk will simply be overlooked.

How to reduce the risk: While wood dust undoubtedly poses a serious fire threat, there are several options available to engineers, plant managers and risk managers to mitigate the potential hazard.

Where possible, explosive wooden waste materials,and/or collection and storage silos, should be located outdoors. If the collection units or silos are indoors, it’s essential that precautions are taken depending on the size and construction of the unit, its proximity to people and machinery nearby, and how close it is to walkways, exits, ignition sources and combustible materials.

Mitigating steps must be taken to avoid the risk of fire or secondary explosion such as preventing dust accumulating through the factory, installing sprinkler systems, and meticulous housekeeping and ventilation systems (both natural and mechanical) within the building.

Minimise hot work: So-called ‘hot’ working – the practise of cutting the materials by welding or flame cutting equipment – is a common ignition source that can result in a fire, and it should be avoided where possible (e.g. by using cold cutting methods). It’s almost impossible to avoid this practise completely. However, we recommend you minimise the exposure to this risk by using a formal, recognised hot work permit system.

A formal permit system allows factories to control and manage the risks that hot work presents, provided they are implemented and controlled properly. For example, companies should make sure that equipment and work areas are cleaned before work starts. The most critical aspect of hot work permit control is the ‘fire watch’ – i.e. the documented periodic inspection of work areas and equipment after hot works have been completed, as this is where a fire can typically start.

Spark detection and extinguishing systems: When dealing with sawdust fires and explosions, apart from the usual means of fire protection such as sprinklers and fire extinguishers, using industry-recognised spark detection and extinguishing systems is also recommended. These systems are exclusively designed to prevent the hazard of sawdust and fire explosions and can therefore greatly reduce the risk.

Spark detection and extinguishing systems are built into the ducts and areas of the plant and machinery that exclusively deal with sawdust. The idea is to detect a spark when it occurs, then immediately extinguish it – either by a built-in water mist/spray system or inert gas extinguishing medium – so that it cannot propagate into a fire or explosion.

Maintain plant and machinery: One of the major causes of sawdust fires and explosions is the age of the plant and machinery, and the corresponding maintenance of them. Aged or poorly maintained plant and machinery can be a source of ignitions and sparks. To address this, robust, well documented maintenance plans and schedules are essential.

Another measure is to replace or refurbish plants and machinery that are electric powered and/or directly involved in the processing of wood, such as de-barking machines and chipping machines. If these machines aren’t properly maintained, they could produce a single anddevastatingspark.

Good ventilation: All factories are different, but wherever possible, they should all strive towards having sufficient ventilation and space to ensure sawdust doesn’t accumulate.

Ventilation can be divided into two main categories.First isnatural ventilation, for example trhoughhe use of open-sided buildings, adequate provision of doors, windows and other openings in a workspace The second ismechanical ventilation. An example is the use ofpneumatic dust collection systems with adequately protected ducting, localised exhaust ventilation (LEV) systems withadequately protected ducting and extraction fans.

Another method of mitigating the risk of sawdust explosions is explosion venting (installing explosion-relief vents),This typically means have bursting panels or explosion doors, directly unto machinery and ducting that produces and/or handles sawdust.

Working with businesses to reduce their risk

Sadly, many businesses find out the hard way that sawdust fires and explosions are a real threat.

At Allied World, we want to be a resource for assisting in identifying areas of concern. After all, a competent insurer, one that knows the wood industry and the associated risks, can provide advice and insist on safety measures in order to take necessary steps to mitigate against the risk of fire and explosions.

This will result in fewer deaths and serious injuries in these workplaces, and a reduction in the economic losses that come with these catastrophes.

Hiresh Das is a risk engineer with Allied World, based in Malaysia. He has over 20 years of experience in the property insurance industry, mainly focused on developing risk management systems for various heavy industrial plants and their operations. Industries he has worked with include metal, timber, textiles, chemical and food. Hiresh has worked with a range of Fortune 500 clients to support them in avoiding risk all over Asia.

This information is provided as a risk management resource and should not be construed as legal, technical or clinical advice. Consult your professional advisors or legal counsel for guidance on issues specific to you. This material may not be reproduced or distributed without the express, written permission of Allied World Assurance Company Holdings, Ltd (“Allied World”), a Fairfax company. Risk management services are provided by or arranged through the Australia, Hong Kong or Singapore branches of Allied World Assurance Company, Ltd, a member company of Allied World incorporated in Bermuda with limited liability. © 2020 Allied World Assurance Company Holdings, Ltd. All rights reserved.

-

Allianz General | Allianz General combines innovative protection solutions while powering social good to lead Malaysian market

The carrier proactively addresses emerging risks and evolving customer protection needs while giving back to the community.

-

Sedgwick | Asia’s Energy Transformation – Balancing Growth, Risk and Renewables

Energy market presents unique risks, especially in a region which includes China and Japan as well as developing nations like Vietnam and the Philippines.

-

Beazley | Turbulent Waters: the maritime energy transition challenge

Businesses are facing a complex transition to non-carbon energy sources amid a push to achieve net-zero emissions for the marine sector by 2050.

-

Aon | Navigating shifts in the global and Asia insurance markets

Neelay Patel, Aon head of growth for Asia, says the market in Asia is at an ‘interesting stage of the cycle’.